Who We Are

About Us

Afri Regen is a mauritous registered company which uses the Afri Regen patented technology for the regeneration of all types of lead acid batteries.

Afri Regen established the first fully operational regeneration centres in Japan and Turkey in 2011.

Between 2015-2019. similar regeneration centres were opened in Azerbaijan, Myanmar, Thailand and Pakistan

Afri Regen technology is now operational in several countries, regenerating between 15,000 and 20,000 AGM/gel batteries per

month.

Afri Regen Works is currently targeting the African market, and will be establishing battery regeneration centres throughout Africa.

Afri Regen regeneration techniques can give a failing battery another 2-3 years of excellent performance, allowing you to reduce your carbon footprint, cost and overall economic impact dramatically.

Contact us today to find out just what we can do for you, or click here to learn more about our organisation.

Afri Regen TechnologyTECHNIQUES

OUR facilities

What Does Afri Regen Do?

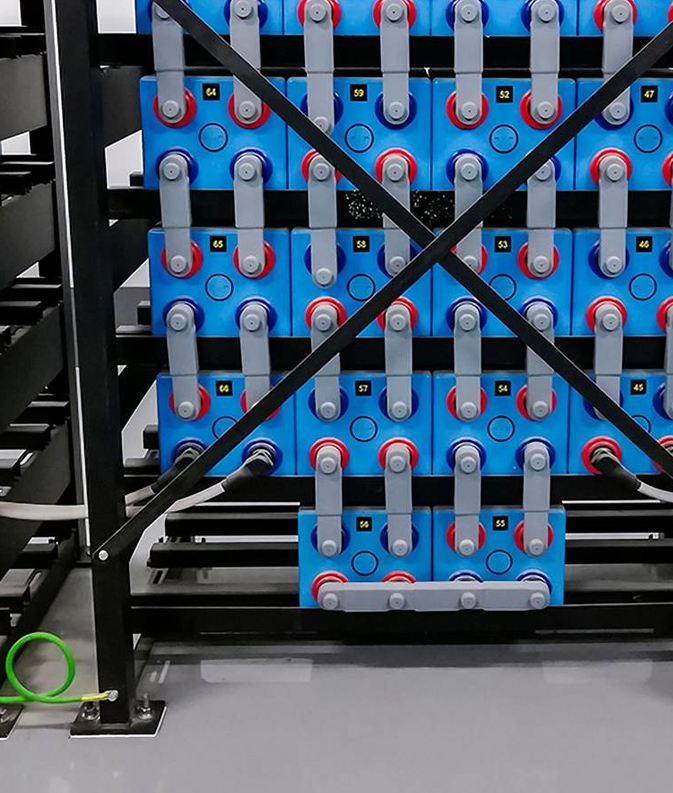

Afri Regen develops technology for the regeneration of all types of lead acid batteries. We operate across three continents, regenerating between 15,000 and 20,000 AGM/gel batteries per month.

We began in 2011 when we established state of the art regeneration centres in Japan and Turkey. The technology footprint has expanded to include the following countries: Azerbaijan, Cyprus, DRC , Ethiopia, Georgia, Japan, Myanmar, Pakistan, Thailand, and Vietnam.

Furthermore, Afri Regen owns the rights to establishing battery regeneration centres throughout the African continent.

How Battery Regeneration Works

- Batteries lose capacity due to crystallization of the sulfate from the electrolyte.

- Afri Regen regenerators are able to reverse the crystallization process through pulse technology.

- Batteries are not opened, and only distilled water is added.

- Regeneration may be attempted twice, and is considered successful once the battery achieves 85% or more of its original capacity.

- All successfully regenerated batteries will be tested in 3 C3 charge-discharge cycles.

- Should the battery show a capacity below 85% within these 3 cycles, the regeneration is not considered successful.

- After finishing the whole process, all successful batteries will be charged, cleaned and labelled with Afri Regen branding. The batteries are now ‘as good as new’.

- Labels are marked with a record of entry date, delivery date, voltage, amperage, IR and capacity.

What we provide

Our Services

Research & Development

We benefit from the Afri Regen consulting R&D centre which works continuously to refine the Afri Regen technology, techniques and equipment, as well as developing completely new battery regeneration solutions.

Technical Start-Up Support

We make it possible for our local partners to keep our shared regeneration centres in full compliance with local and international Health & Safety and Environmental standards, and to operate with very low CO2 footprints.

Operational Support

We offer 24hour support to the local staff during the regeneration process. Selecting the right batteries and applying the correct settings to the equipment to achieve the highest success rate in the regeneration process of the selected batteries.

Business Development

We are always looking into new opportunities to create battery regeneration centers in new countries for our customers.

Financial Support and Investment

In addition to operational support we can offer new local partners financial support to get a centre up and running. This allows us to expand our network more efficiently and with the correct infrastructure from the outset.

Quality Control Support

Our audit teams perform quality checks at all of our operational centres, ensuring that our customers only receive the highest quality work and the most reliable regenerated batteries.